Digital or offset print?

What’s better: digital or offset? When you put the question like that, there can only be one—entirely unsatisfactory—answer: it depends. On what? The number of copies to be printed, the time to complete the job, the required format, finances—obviously, as well as several other less significant factors. The thing is that a solution fitting for Smith might well give Jones a headache and turn some of his hair grey.

However, one thing has to be made clear before we plunge into the intricacies of printing technologies: we will be analysing digital and offset methods looking from the perspective of what we know best, which is book printing.

Offset printing

At the moment offset printing is the most common printing technology. It means considerable expense, however the investment will pay for itself when printing long runs. Before you make the decision to go with offset, take into account the relatively long time required to complete the job. As offset printing is a complex technology, the preparation for printing itself takes more time than with digital.

The offset printing process is easiest compared to stamping, the difference here being the use of printing plates, i.e. aluminium matrices, produced using the CTP imaging technology in place of a stamp. And the need to prepare the matrices is the reason why an offset printing job requires a longer time to complete. The matrices are attached to printing cylinders. However, the image prepared on the matrix is not transferred directly onto paper; it is first imprinted on a rubber covered roller and only then the image is transferred from the roller to paper.

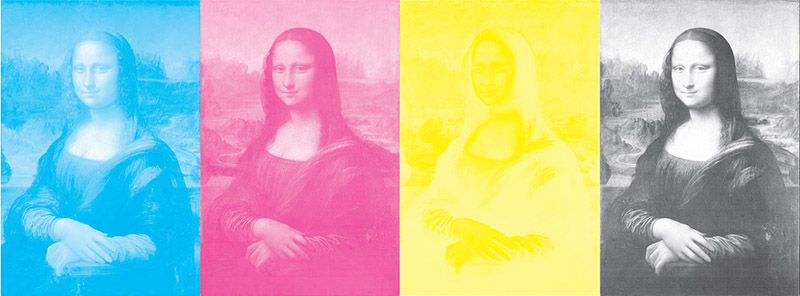

Remember, of course, that this is the CMYK colour space, where each of the four component colours (i.e. cyan, magenta, yellow and black) requires the use of a separate printing plate. To come out with a sheet printed in a full range of colours the image has to be successively transferred onto the paper from four individual plates.

Each printing plate transfers only one CMYK colour; these are the images transferred from the individual matrices.

All four component colours are transferred onto paper in sequence, as a result of which the range of colours of the final image is expanded during the successive printing phases.

The good quality of the final product is the main reason for offset’s popularity. Another advantage as far as offset printing is concerned is the option to use the Pantone colour palette, which enables us to refine the materials printed with metallic and neon inks. Obviously, using a fifth colour means that an additional matrix will have to be produced.

Digital printing

The key and most important quality of digital printing is the fact that it does not require the use of any pre-prepared printing plates. Computer data is transmitted directly to the printing device, which enables us to print practically instantaneously. The absence of matrices means that the time required to complete the job is shorter, on top of which we do not incur the cost of having to produce the matrices. The printing of each individual copy is a stand-alone and final process.

Another advantage of digital printing is without doubt the option—not to mention the financial viability—of printing shorter runs. This is the decisive argument for a great deal of people, however printing short runs means further benefits which an enterprising investor will be glad to make us of. Digital printing gives the option to take an extremely free approach to managing the printing process, i.e. you can split your print runs into smaller tranches of the same number of copies and print them as and when required. We are not only able to speedily respond to the market’s demand for our published materials, but also have the opportunity to entirely eliminate all storage costs. Additionally, we do not doom our books to a pointless existence in conditions that are not always book-friendly, at the end of the day books are not like wine and aging isn’t good for them). Moreover, short runs are a great tool for probing the market—we can always print a few dozen or a few hundred books to see what the readers’ reaction is and base our decision as to the final size of the run based on it. Once we know how many copies we want to print then there’s nothing stopping us from checking what our book—the final product—is going to look like. This is what a test print is for, which in reality is nothing else than a copy of our book identical to the subsequently printed run that can be used to e.g. review the accuracy of the book’s content.

Yet another quality of digital printing deserving a special mention is personalisation. As we already know, the printing of each individual copy using the digital technology is a stand-alone and final process, which means that changes can be introduced to each copy. We can change details such as first and last names, sections of the texts, barcodes, even photographs and graphs. The offset printing technology does not provide room for manipulations of this type—the smallest change would require a new set of printing plates.

What about quality?

As far as this category is concerned, offset printing used to win hands down. Numerous industry publications praise the superiority of offset over digital without the slightest doubt; meanwhile, this is not such an obvious matter. In the past the quality of offset was not attainable for digital. However, time passes, technology is developing at an extreme pace and the tide is steadily turning in favour of digital printing. The UV digital printing technology is particularly worth a mention as it delivers excellent printing quality.

In addition, remember that the substrate used also affects the final product. Offset printing looks better on coated papers as uncoated materials absorb more ink, thus resulting in less intensive colours.

What do we go with then?

As already stressed in the introduction: it all depends on the specific requirements of each given job. Offset printing will be more financially viable for longer runs, however you have to take into account the time required to complete the job. If we have deadlines to meet and we don’t need to print tens of thousands of copies, then digital printing will be more cost-effective. However, if you’re still in doubt whether you’re making the right decision, and the information found on the Internet—instead of giving you clarity—is only confusing you more, do not worry, no one can be an expert on everything! The best solution here is to contact a representative of a printing house. A professional advice coming from someone with the experience needed will without doubt help you make the right decision.